The chemical industry is evolving rapidly. Regulations are tightening, sustainability requirements are increasing, and every decision, from selecting a reagent to approving a batch, has a direct impact on safety, compliance, and your company’s competitiveness.

In this context, mastering quality and traceability is no longer just a regulatory obligation. It is a strategic driver.

From sourcing raw materials to batch release, including analytical controls and process monitoring, everything must be documented, verified, and optimized.

Our teams support chemical, pharmaceutical, and biotech companies every day, all driven by the same ambition: combining industrial performance, regulatory compliance, and quality excellence.

Mastery without compromise: the realities of modern chemistry

As you experience daily in the chemical industry, production runs continuously or in successive campaigns, involving sophisticated equipment, diverse raw materials, and complex processes.

Every synthesis, every transfer, every measurement must be tracked and controlled.

Regulations, from the REACH regulation to CLP requirements and ISO standards, govern every step of the product lifecycle. Far from being a barrier, this framework ensures employee safety, environmental protection, and reliable deliveries.

But chemistry is changing. The shift toward a more sustainable industry is redefining practices: reducing carbon footprint, substituting sensitive substances, valorizing co-products.

Quality and HSE teams have now become true drivers of transformation.

And then there are your customers, increasingly demanding when it comes to traceability, transparency, and compliance. They expect robust guarantees, up-to-date certificates, and documented proof of the quality and safety of the substances used in their own processes.

Chemical quality is no longer just technical compliance. It is a commitment to trust.

Digitizing quality for better production

In the chemical industry, digitalizing quality and traceability is no longer optional. It is essential.

The challenge is no longer whether to do it, but how to do it intelligently, without overcomplicating processes or multiplying tools.

This is the purpose of Smart Quality, our solution developed by Idealis Solutions, designed for chemical, pharmaceutical, and biotech stakeholders.

They allow you to strengthen traceability, simplify compliance, automate controls, and streamline quality management on a daily basis.

1. Full traceability for every batch

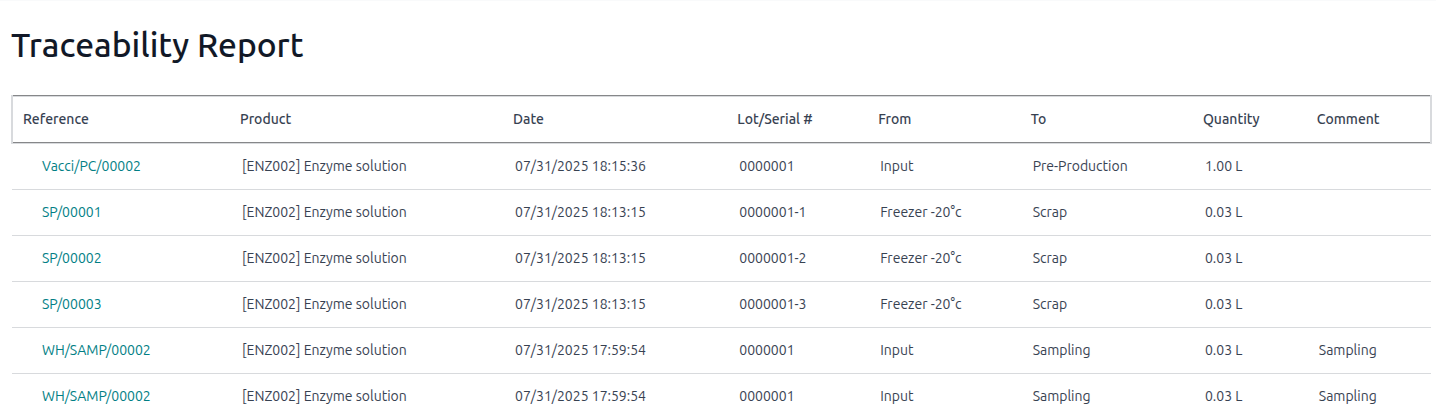

In the chemical industry, every operation matters. Smart Quality centralizes all information in a single, visual platform, allowing you to track batches, analyses, critical parameters, and production steps in real time.

Concrete example: During an active ingredient synthesis, an analytical deviation appears. In seconds, Smart Quality identifies the supplier batch, receipt dates, transfers, and sampling operations. Your teams can investigate, correct, and document without interrupting production.

The result: exhaustive, instant traceability, essential during audits or regulatory inspections.

2. Simplified compliance without administrative overload

Each substance requires complete documentation: certificates of analysis, technical sheets, compliance reports.

Smart Quality automates this complex document management. Certificates and reports are automatically linked to the corresponding batches, ensuring immediate, reliable, and up-to-date access.

During an audit, one click is enough to retrieve the compliance evidence for a substance or synthesis intermediate. No more time-consuming searches. Compliance becomes seamless and fully integrated.

3. Automated controls to boost efficiency

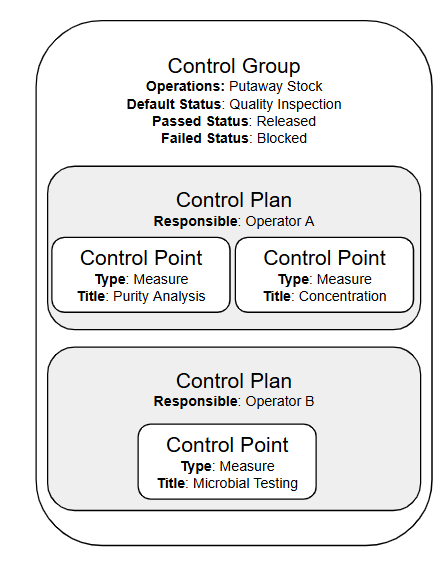

Between physicochemical analyses, stability testing, and purity checks, your laboratories perform hundreds of daily controls.

Smart Quality automates scheduling based on your own rules: operation type, product, frequency, quality history.

Its Dynamic Frequency feature automatically adjusts the control frequency based on results. It becomes more intensive when anomalies appear, and lighter during stable periods.

Your teams gain time, consistency, and responsiveness.

For example, when launching a new production campaign for a specific polymer, Smart Quality automatically triggers the predefined controls on the initial batches of monomers and catalysts, in accordance with the configured control plans. The frequency of these checks then adjusts dynamically based on the results obtained. This allows your teams to gain in efficiency, consistency, and responsiveness.

The result: laboratories focused on analysis and improvement rather than administrative planning.

4. Anticipating risks and driving continuous improvement

In the chemical industry, risk management is essential. A temperature deviation, an uncontrolled parameter, or a substance incompatibility can have major consequences on safety and quality.

Smart Quality tracks every corrective action: identified cause (contamination, impurity, parameter deviation), actions taken, and follow-up until resolution. Its complete traceability of batches, raw materials, operations, and analytical results enables rapid investigation and quality trend detection.

Recurring data analysis helps anticipate deviations and optimize processes. Historical measurements and analytical reports transform reactive management into proactive improvement, supporting more controlled, safer, and high-performance production.

Smart Quality, your ally for high-performance and responsible chemistry

The Idealis Solutions team relies on listening, proximity, and co-design to make Smart Quality far more than just a tool: a true partner fully integrated into your industrial and quality culture.

From assessing your needs to training your teams, our mission remains the same: empowering you to be autonomous, confident, and high-performing in mastering your processes.

👉 Discover how Smart Quality can transform your approach to quality and traceability, and contact our Idealis Solutions experts for a personalized demonstration. Contact us

Smart Quality: Mastering quality and traceability in the chemical industry